Manufacturing is on the brink of a major transformation, fueled by the power of Generative AI. No longer confined to just automation, AI technologies are supercharging the entire manufacturing process. From creating revolutionary product designs to predicting equipment failures before they happen, AI is turning traditional manufacturing practices upside down.

According to research, the U.S. market for generative AI in manufacturing is set to skyrocket from $70.88 million in 2022 to over $2.1 billion by 2032.

This explosive growth is being driven by companies looking to enhance efficiency, reduce costs, and innovate like never before. So, what exactly is Generative AI doing in manufacturing? Let’s dive into the top 10 use-cases where AI is revolutionizing the industry and transforming the way manufacturers operate.

1. Supercharging Product Design

Traditionally, product design involved a long cycle of iterations and approvals. Generative AI is flipping that on its head. By analyzing vast amounts of past design data, AI generates multiple design options in minutes, providing new and innovative ideas that save time and reduce costs.

Old Way: Lengthy design iterations and approvals.

New Way: AI-driven design options generated in seconds, with faster iterations and reduced production timelines.

2. Predictive Maintenance

Predictive maintenance is one of the most game-changing applications of generative AI in manufacturing. AI analyzes data from equipment sensors to predict failures before they happen, reducing unplanned downtime and saving millions in maintenance costs.

Old Way: Reactive maintenance that often leads to costly downtime.

New Way: Real-time monitoring of equipment with AI flagging potential issues before they occur.

3. Demand Forecasting

Generative AI is drastically improving demand forecasting by analyzing historical sales data, market trends, and other external factors. AI-generated forecasts enable companies to manage inventory better, ensuring that manufacturers meet demand without overstocking or understocking.

Old Way: Guesswork and reactive stocking strategies.

New Way: AI-powered forecasting for smarter inventory decisions.

4. Custom Manufacturing

Generative AI enables personalized or on-demand manufacturing by automatically adjusting production processes based on specific customer orders. This results in highly flexible manufacturing lines that can cater to unique product demands without compromising efficiency.

Old Way: Static production processes not easily adaptable to customer-specific demands.

New Way: AI-powered customization allowing for greater production flexibility.

5. Supply Chain Optimization

AI is optimizing complex supply chains by analyzing real-time data to streamline logistics, reduce inefficiencies, and improve delivery times. This ensures that manufacturers can keep their production lines running smoothly even when external conditions change suddenly.

Old Way: Reactive and inefficient supply chain management.

New Way: AI-generated optimization for real-time supply chain adjustments and improved logistics.

6. Quality Control

AI-powered quality control systems are enhancing production by detecting defects with pinpoint accuracy. By analyzing patterns and performance data, AI systems flag anomalies that might be missed by human inspectors, leading to higher quality products and reduced waste.

Old Way: Manual inspections prone to human error.

New Way: AI-driven quality control with real-time defect detection.

7. Energy Efficiency

AI is also helping manufacturers reduce their energy consumption by analyzing energy usage patterns and making real-time adjustments. By optimizing machine operations and shutting down unnecessary processes, AI significantly cuts energy costs.

Old Way: Reactive energy management that led to inefficiencies.

New Way: Real-time AI monitoring for smarter energy usage.

8. Automating Documentation and Compliance

Generative AI automates the creation of documentation and ensures compliance with industry standards. This reduces the time spent on manual tasks and ensures that all regulatory requirements are met accurately.

Old Way: Time-consuming manual documentation and compliance checks.

New Way: AI-generated reports and automated compliance management.

9. R&D Innovation

By analyzing previous experiments, customer feedback, and current market trends, generative AI helps companies accelerate their research and development efforts. AI generates new ideas, tests prototypes, and delivers insights that speed up the R&D process, helping companies stay ahead of the competition.

Old Way: Slow and expensive research and development processes.

New Way: AI-powered innovation with faster turnaround times.

10. Smart Workforce Management

AI tools can manage workforce scheduling, optimize shift allocations, and even predict staffing shortages. This ensures that manufacturing plants run smoothly, with the right number of workers assigned to each task, minimizing downtime and maximizing productivity.

Old Way: Reactive workforce management with inefficiencies in scheduling.

New Way: AI-driven workforce optimization for better resource allocation.

Call to Action: Supercharge Your Manufacturing with Blueprints Digital Center

At Blueprints Digital Center, we specialize in integrating Generative AI solutions that revolutionize manufacturing processes. Whether it’s product design, predictive maintenance, or supply chain optimization, our team can help you harness the power of AI to take your manufacturing operations to the next level. Contact us today to explore how we can drive efficiency, reduce costs, and fuel innovation in your manufacturing business.

FAQ‘s

1. How does Generative AI improve manufacturing?

Generative AI optimizes various aspects of manufacturing, including product design, maintenance, supply chain management, and quality control, resulting in cost savings and increased operational efficiency.

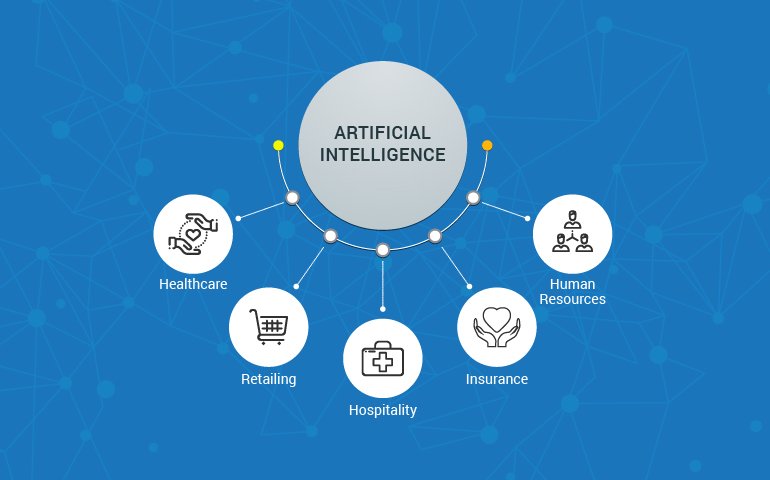

2. What industries can benefit from AI in manufacturing?

Industries such as automotive, electronics, pharmaceuticals, and aerospace are adopting AI-driven solutions to boost efficiency and innovation.

3. Can AI help reduce manufacturing costs?

Yes, AI helps reduce costs by automating maintenance, optimizing energy usage, and improving production efficiency, which reduces waste and downtime.

4. How reliable is AI in quality control?

AI-powered quality control systems are highly reliable, detecting defects with more accuracy than manual inspections, ensuring consistent quality output.

5. How does AI contribute to sustainable manufacturing?

AI improves energy efficiency by optimizing machine usage and reducing energy waste, contributing to more sustainable and eco-friendly manufacturing practices.